- Methodologies: sparse learning guided by physics, Gaussian process, linear regression.

- Applications: fuselage assembly, ship assembly, multistage manufacturing process

Contents

1. Projects

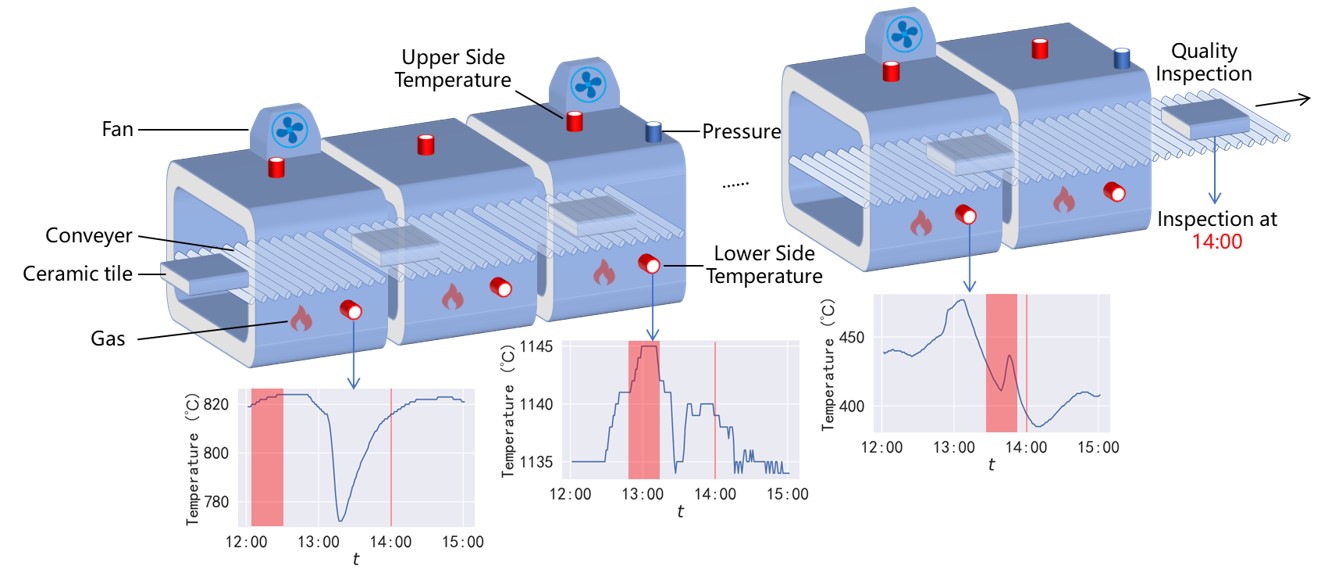

1.1. Automatic Data Synchronization and Identification of Crucial Phases and Variables in the Ceramic Firing Process

Students: Yukun Xie

Motivation

-

The firing process for ceramic tiles is a MMP process with multiple sensors to monitor the temperature, pressure and equipment parameters. The data contains rich information

-

The streaming data collected from sensors are separated and not related to the quality characteristics of each product

Objective

- Synchronize the continuous sensor data into product-oriented data and to conduct relationship mining in MMPs

Challenges

- Time delay

- Missing sensors and multiple sensors at some stages

Proposal

- Automatic data synchronization to get the product-oriented mixed data

- Model the relationship between the mixed data and quality characteristics